502 205 SGRASSANTE PER METALLI SPRAY (62)

All metal surfaces, ferrous and non-ferrous, including also some plastic supports of thermoplastic origin, not sensitive to solvents, show traces of greases or presence of oil, siliconic and non-silicon, water based, animal or synthetic. This presence of pollutants, even if it is not evident, reduces the ability to crimp and fix of inks, overprinting power of and varnishes. Quasar srl has formulated 502 205 DEGREASER FOR METAL SPRAY to obtain a perfect degreasing of polluted surfaces. This product combines rapid use with low harmfulness. Its action is effective every kind of lubricating grease both animal and synthetic origin. Just a quick passage with a rag on ferrous or non-ferrous metals, anodized or raw, stainless steel, thermosetting surfaces, glass etc. is sufficient to obtain a deep and complete degreasing of the surface. The completely degreased surface helps a better anchorage of mono and two-component inks.

290.54 APRIMAGLIA

290.54 APRIMAGLIA is normally sprayed on the print side of the frames to prevent ink drying loosening in the loops of the frame during work breaks. The particular solvent mixture is perfectly compatible with all Quasar production inks. After the work break, just a few prints on waste paper are enough to return the frame in optimal printing conditions. Therefore it is not necessary rubbing with a cloth on the application surface.

400.040 PRIMER SPRAY PER TERMOINDURENTI

All surfaces of untreated metal origin, thermosetting resins, Bakelite, glass, lacquered wood etc. can interfere with anchorage of digital inks and also silk-screen printing inks. In case of oxidized metals, the support must first be deoxidized. 400.040 SPRAY PRIMER PER TERMOINDURENTI manages to anchor itself to many thermosetting or similar surfaces, refractory to printing. The product must be sprayed with a veil on the substrate to be printed, in small quantities. Wait until the veil of 400.040 SPRAY PRIMER PER TERMOINDURENTI goes out of powder and immediately overprint it with Epoxeri type 270 screen printing inks, 272 Thermolux, 273 Metalsheet, 225 Omnialux, 262 Nyloflex or other families of inks that need to be tested. Tou can also print with your supplied digital inks both solvent and U.V.

502 LINEA SPRAY

Additives and complementary products for digital, silk-screen, pad printing and offset printing. They have very different characteristics and are used to solve most of the daily printing problems. They improve the adhesion of the inks on the supports, create protective barriers, solubilize inks, help T.shirt adhesion to the printing tables, etc.

Spray cans are all produced in 400 cc format. and they all comply with security rules on workplace. Produced in the dedicated internal plant, they contain a latest generation propellant, DME (ether), non-suffocating gas that does not damage ozone (it is not a greenhouse gas)

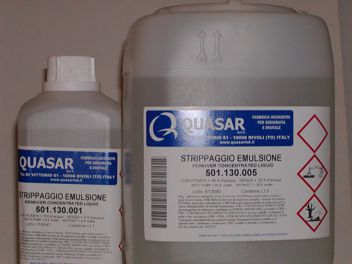

501.130 STRIP LIQUIDO

501.130 LIQUID EMULSION COUPLING in contact with most emulsions, even very old and sedimented, makes possible recovering the frames. The mechanism of strong oxidation produced on the components of the emulsions, makes them solubilize in water.

ATTENTION: due to the oxidizing nature of the product, containers and containers made of metal and stainless steel must not be used, because 501.130 SHAMPING LIQUID EMULSION will immediately deteriorate them. We recommend polypropylene or polythene plastic bins.

502.175 LORITAC SPRAY ADESIVO

Adhesive spray based on acrylic resins in solvent of irritant category. 502.175 LORITAC is the result of the combination of dissolved resins in solvents with low environmental impact and a study on propellant gases that do not damage the environment. Spray on the printing bed and wait a few minutes for complete drying. After drying, 502,175 LORITAC develops a large self-adhesive capacity. It remains very dry on the surface and does not release any residue on the support. T-shirt resistance is remarkable.

400.024 SPRAY PRIMER PER POLIPROPILENE

All surfaces of polyolefinic origin can reject anchoring of digital and also silk-screen inks.

400.024 PRIMER SPRAY FOR POLYPROPYLENE anchores to many polyolefin surfaces refractory to printing and it allows anchoring. It adheres in particular to PP polypropylene, PE Polyethylene LD, PB Polybutene, Ionomers, cellulose acetate sheet, PETG, extruded methacrylate, natural leather etc.

In particular, the adhesion on polyolefins, a thermoplastic material that can not be damaged by solvents at room temperature, also adheres to many materials whose surface tension is < 39 dyne (m/Nm).

400.030 PRIMER SPRAY PER POLIAMMIDI

All surfaces of polyamide, polyurethane and even thermoplastic origin may refuse digital and also silk-screen inks. Especially glass-filled Nylon can give poor adherence to the printed ink as well as sheet polycarbonate. In these cases, since in digital printing it is not possible to change ink or ink family, 400.030 PRIMER SPRAY PER POLIAMMIDI solves many problems of anchoring printing inks without affecting or damaging the surfaces on which it is sprayed. The components of 400.030 PRIMER SPRAY FOR POLYAMIDES have a very rapid action on almost all types of polyamide.